|

Optoelectronics

Series |

|

PowerWash™

Aluminum

Organic Polymer Cleaner AHLR03

|

|

It

is very common that the particles created

by plasma processing accumulate on the

surface of equipments in vacuum chamber

of dry etching if they are not abstracted

in time. Day after day, these particles

probably polluted the parts for etching

process. According to the figure, after

cleansing by PowerWash™

AHLR03, the organic adhesion is obviously

removed and the subject of aluminum

alloy, anodic film, and cladding material

are not either influenced or hurt.

PowerWash™ AHLR03

is also successfully applied for

cleansing polyimide vacuum chamber of dry

etching. |

|

|

|

PowerWash™

Removable Adhesive Cleaner

AHLR03-GU |

|

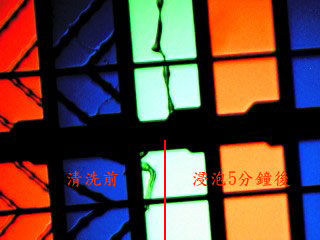

To avoid scratches, the glass panels or

mirror metal panels are usually covered

by protective film or spayed by removable

UV cured adhesive. Previously, the

residual adhesive was artificially wiped

after peeling off the removable film.

But there will be residues which are not

easy to remove if CNC cutting, polishing

and etc processes are included in

pre-process. The traditional artificial

method is time-consuming. The brand new

Power Wash™ AHLR03-GU neutral adhesive

remover is competent to rapidly get rid

of the residual adhesive in ultrasonic

cleaning machines or roller brush

automatic cleaning machines without

harming ITO, aluminum panel, aluminum

wire and … etc soft metal.

More.. |

|

|

|

PowerWash™Particle

Cleaner PTC09B |

|

The structure and material of OGS touch

panel is more complex, and the ITO

circuit, aluminum wire, silver wire,

cooper wire and SiO2 coating layer on

most OGS panels are exposed

simultaneously. Moreover, certain OGS

panels are even with IGZO (Indium gallium

zinc oxide), anti finger Stan fluoride

and AR coating. To automatically clean

the OGS panels is getting more and more

difficult for the high requirement of

cleaning without affecting electrical

property.

Now, the neutral dust particle cleaner,

Power Wash™

PTC09B, is capable to efficiently clean

OGS panel but not influent OGS electrical

property, ITO resistance value as well as

transparency clarity. In order to

decrease the artificial loading, PTC09B

has been successfully applied on

automatically cleansing line, and has

provided higher cleanliness and

stability.

|

|

|

|

PowerWash™Particle

Cleaner PTC17 |

|

The outer frame of lens is required to be

cured with oven after being coated by

black ink GT7. And it is hard to prevent

the outgas problem outside the touch

panels or LCD during UV cured or heat

cured processes no mater either wire

marking or photomask is adopted for BM

process. The dissociative resin monomer

will be enclosed to the visual range or

graphic area of panel, and then turn into

formidable particle. This kind particle

is much harder to be cleaned than normal

greasiness, dandruff and dust as a result

of its characteristic of hardenable

organic polymer.

The new-developed particle cleaner, Power

Wash™

PTC17, adopts the latest interfacial

agent, and it is competent to permeate

and to cover the resin particle. The

resin particle will be easily removed

from the object without harming the cured

GT7 ink. Power Wash™

PTC17 has been successfully applied on

cleansing of lens, wafer and high pixel

image sensor.

More.. |

|

|

|

PowerWash™

Cured Ink Cleaner

ACHM01-G |

|

GT-7 is the black epoxy ink which has

been used on cover lens in optical

industry for a long time. We are able to

find ink remover which belong to strong

alkalinity,but

this kind ink cleansing agent is not

competent to clear the ink. In addition,

the effective duration of strong

alkalinity ink remover can’t last due to

GT-7 contains coal tar. In respect of the

acidity ink remover, they are not only

always with strongly irritant smell but

also corrosive and harmful to metal

fixtures.

We have overcame all above shortages of

traditional ink remover, and the whole

new cured ink cleansing agent Power Wash™

ACHM01-G is with long shelf life, and

light smell. There will be not residue

left after using Power Wash™

ACHM01-G to remove the cured ink.

Furthermore, the innovated glue type ink

remover, Power Wash™ ACHM01-GG, is able

to vertically attach on the wall but not

drop. Power Wash™ ACHM01-GG can

successfully replace dichloromethane, and

to be applied on removing the insulated

paint of varnished wire.

More.. |

|

|

|

PowerWash™

Cured Ink Cleaner

ACHM04-A |

|

It is quite hard to avoid the excessive glue while wafer packing,

thus, to rapidly remove the cured

excessive glue is extremely important for

efficient production. Moreover,

“permanent consistence”(inclusive of

wear-resist, light-proof, heat-resist,

acid-resist, alkali-resist) is emphasized

on EPOXY, PU or ACRYLIC series AB curing

adhesive.

However these features increase the

difficulties of cleansing.

Now, the most creative cured ink

cleanser, PowerWash™ ACHM04-A, is

extensively applied on glue cleansing

requirement of variety material for its

neutral pH value.

More.. |

|

|

|

PowerWash™Particle

Cleaner PTC13 and PTC18 |

|

There are more and more types of coating layers upon the various

requirements of glass, lens, prism and

diagonal mirror (for instance: antiglare,

antireflection, red/blue light filter,

anti finger contamination…and so on).

The PowerWash™ particle cleaner PTC13

has been successfully applied on removing

organic polymer coating layers like

epoxy, acrylic, PU and …etc. Furthermore,

PowerWash™ particle cleaner PTC18

is capable to easily peel off the

inorganic metal coating layers like SiO2,

TiO2, Ti3O5, MgF2, Ta2O, Al2O3 and …so

on.

More.. |

|

|

|

洗威™ 氧化銅擦拭劑CuP01 |

|

|

After using for a while, gold fingers are

always covered by oxides, and it will

cause bad connection. In order to prevent

the defective contact, assembly factories

are used to applying certain polished

material (like toothpaste) to wipe off

oxides before assembly

(packaging), but the polished material is

easily left and uneasily to be removed. After using for a while, gold fingers are

always covered by oxides, and it will

cause bad connection. In order to prevent

the defective contact, assembly factories

are used to applying certain polished

material (like toothpaste) to wipe off

oxides before assembly

(packaging), but the polished material is

easily left and uneasily to be removed.

The PowerWash™ CuP01, CuO cleaning agent,

can efficiently remove the oxides. The

PowerWash™ CuP01 is rapidly volatile so

that it will not be left on the gold

fingers or contact points. In addition,

the PowerWash™ CuP01 is completely

soluble in alcohol, and this feature will

ensure you “no residue “ if you use

alcohol to wipe the contact points after

applying PowerWash™ CuP01.

More.. |

|

|

|

PowerWash™

Cured Ink Cleaner

ACHM01 |

|

|

“Permanent consistence”(inclusive of

wear-resist, light-proof, heat-resist,

acid-resist, alkali-resist) is vitally

emphasized no matter on thermosetting ink

or UV cured ink. But the unrespectable

defects still happen in production.

Sometimes the ink reveals or blooms, and

sometimes it spreads non-uniformly;

Sometimes

Now we develop the best cured ink

cleaner, PowerWash™ ACHM01,to help you

easily solve above difficulties. In

addition, PowerWash™ ACHM01 is also

competent to remove the epoxy resin which

is overflowed on plate or glass while

assembly

(packaging). |

|

|

|

PowerWash™

Synthesis

Glue

Debonder,

SynGC01~07 |

|

|

Either sheet OCA (optically clear

Adhesive) or liquid OCA is adopted, there

are still various lamination defects

occurred while laminating OG of touch

panel and sensor. The PowerWash™ natural

tangerine oil glue debonder NGC01 and

NGC02 are capable of rework. Moreover,

the PowerWash™ synthesis glue debonder,

SynGC01~07, are developed for diverse

adhesive cleaning requirement of PSA

adhesive produced by different

manufacturers.

The flash point of synthesis glue

debonder (>80℃)is higher than natural

gule debonder’s. The smell of synthesis

glue debonder is lighter and it is more

complied with the requirements of

industrial safety.

More.. |

|

|

|

PowerWash™Silica

Membrane Cleaner SMC03 |

|

|

In

the semiconductor manufacturing process,

the silicon dioxide and silicon nitride

film sediments on the surface by plasma

are very rigidly structured. They can be

eliminated with strong acid but the

stainless steel or aluminum alloy surface

will also be eroded and change its color.

The result is worse than leaving it

un-cleaned. PowerWash™ Silica Membrane

Cleaner SMC03 with a neutral pH value of

7.0 does not harm the metal surface and

is your new choice to fulfill the high

precision demand.

More.. |

|

|

|

PowerWash™ Gallium

Nitride (GaN) Cleaner SMC04 |

|

Plasma Epitaxy Gallium nitride (GaN) is

essential for production of LED,

therefore chambers or trays used for

Vapor Deposition will be polluted by

Gallium nitride. After a while, there are

no other options but to scrap the

chambers or trays if they are not

cleansed.

Power Wash™ SMC04, Gallium nitride (GaN)

cleaner, is now your best solution.

More.. |

|

|

|

PowerWash™ Silicon

Glue Cleaner SGC01 |

|

|

|

|

|

PowerWash™ Silicon

Glue Cleaner SGC04 |

|

|

The common features of ink on Cover Glass (CG, or Cover Lens) are

solid, thick, and uneasy to be removed no

matter the ink is either BM photoresist

of yellow-light process or cured ink

through screen printing. Not only

terrific smell, using solvent stripper

will bring lots of issues like industrial

safety dangers caused by VOC, shelf life

insufficient, and management difficulty

of bath solution.

PowerWash™ silicon

glue cleaner,

SGC04, uses distinguished and particular

surfactant technology. SGC04 is low odor,

long shelf life, and capable to

efficiently remove the multiple organic

polymer, inclusive of PU、nylon、acrylic、PI、PC、epoxy、silica

glue, and anti-glare coating. SGC04 can

generate zeta potential which is larger

than -45mv so that the negative voltage

will be formed between surface of object

or glass and particle. Furthermore, not

only peeling the cured ink, to use SGC04

with alkali-resistance &

short-carbon-chain surfactant but also

efficiently remove variety inorganic and

organic particle.

More.. |

|

|

|

PowerWash™Polyimide

Cleaner |

|

|

The water affinitive functional groups of

polyimide film will decrease as the

baking temperature increases, making

cleansing more difficult. In the TFT/CF

manufacturing process, how to selectively

eliminate the baked polyimide film only

without harming other coats remains a

prioritized issue to be solved. PowerWash™

Polyimide Cleaner PIC01~PIC06 can clean

to mother glass completely before

reprocessing or selectively eliminate

polymide only. Besides eliminating the

low-temp baked polymide film only, its

super strength can clean PI films that

are baked at a high temperature of 400℃

well.

More.. |

|

|

|

PowerWash™Particle

Cleaner PTC04 |

|

Previously, chemically strengthened glass and mother glass were

cleansed with the cleaning products

contain KOH. However, KOH slightly etches

glass. The chemically strengthened glass

whish is soaked in potassium nitrate

liquid will gradually generate Potassium

ion over time, and this phenomenon will

cause glass bloom. Furthermore, the

long-carbon-chain surfactant left on the

glass, and it will be more difficult to

get the glass clean.

The brand new micro particle cleaner,

PTC04, has been the best solution for top

panel manufacturers to cleanse glass.

PTC04 is competent to generate zeta

potential larger then -36mv so that the

negative voltage will be formed between

surface of object or glass and particle.

To use PTC04 with alkali-resistance &

short-carbon-chain surfactant can

efficiently remove variety inorganic and

organic particle.

More.. |

|

|

|

PowerWash™Particle

Cleaner PTC05 |

|

|

In

the manufacturing process for touch-panel

displays, after ITO glass/PET cover the

printed graphics, the acid solution will

start to etch. However, after the etched

tank is used around one week, PVC and

UPVC tank body and pipes will be covered

with gluey particles. Alkaline cleansing

liquids will exercise limited effect and

are less efficient, resulting in reduced

yield rate in later parts of the

manufacturing process. Power Wash™

PTC05 can thoroughly clean the tank body

and pipes with simple soaking and

recurrent.

More.. |

|

|

|

PowerWash™Particle

Cleaner PTC06 |

|

When ITO conductive glass is stored over

a long period of time, indium tin oxide

will vaporize and mix with the micro dust

in the air and then attach onto the other

side of the conductive glass. In a dark

room, one can clearly see the

feather-like or foggy pollutant

attachment. To clean this kind of

pollutant, one should take into

consideration the fact that the

components of the pollutant are similar

to those of the indium tin oxide on the

other side of the conductive glass and

that inadequate cleansing will result

in permanent damage to the indium tin

oxide coating.

PTC06 is the cleaner meant

for this cleansing purpose and has been successfully

applied in the industry

|

|

|

|

PowerWash™Ceramic

Substrate Cleaner |

|

|

|

Suitable for cleaning glass and porcelain

materials; free from toxic halogen

elements such as fluorine, chlorine,

bromine and iodine; free from KOH and HF,

etc and will not result in erosion and

cracks on the surface of the glass and

porcelain work pieces. Can effectively

expand and moisten the yttrium oxide

plasma coating on the quartz fixture,

which can be removed under ultrasonic

vibration without damaging the quartz;

effective forcleaning

oxide attachment rapidly; and 100%biologically degradable

and non-harmful to the environment.

More..  |

|

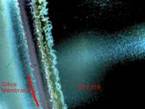

|

|

PowerWash™ Silicon

Glue Cleaner |

|

The silicon series adhesive glues have

good stability. Blaze-endurable,

acid/alkali-endurable, solvent- endurable

and will not embrittle to generate dust.

Extensively used in bonding of ITO plates

and polarizing plates, and the bonding of

pellicle exposed to shorter wave length

and higher joule value and the mask in

the new process of semi-conductor

photo-etching etc. However, the more

stable the performance of the silicon

glue, the higher the difficulty to remove

the silicon glue when the process

requires cleansing. The latest developed

PowerWash™ Silicon Glue Cleaner solves

the problem of silicon glue removal

successfully.

Click here to

view an enlarged picture in which the

silicon glue on the touch control pad of

mobile phone is half removed. |

|

|

|

PowerWash™Particle

Cleaner |

|

PowerWash™

Particle

Cleaner can

be

classified

as neutral,

weak alkali

and strong

alkali.

Available in

both liquid

and powder

form;

suitable for

cleaning of

fixtures or

work pieces

of different

materials.

Can

effectively

remove oil

drops, organ

and

inorganic

particles,

carbon

powder, ash,

magnesium

oxide, and

cerium oxide

grinding

powder, etc;

has been

used for the

cleaning of

pellicle

fixture,

glass

substrate

and plastic

lens

successfully. |

|

|

PowerWash™Recycle

Disk Cleaner RDC01 |

|

|

|

|

PowerWash™Recycle

Disk Cleaner RDC02 |

|

The

Diffusion

Sheet of

backlight

module is

coved many

breads, not

easy to

cleansing

and recycle

the plastic

plate. Now

we can use

RDC02 to

treatment

and recycle

the plastic

film.

|

|

|

PowerWash™Silicium

Powder Cross-Linking Agent SCA01 |

|

The

waste PEG cutting oil from wafer cutting

contains 40~50% tiny

silica powder, which can not be filtered

even within 0.5μm filter bag

(as

figure

below). The

silica powder bridging agent can be added

to the PEGcutting oil to condensate the

tiny silica powder and filter the PEG

cutting oil

that is clarified effectively; can be

used for metal processing or boiler

fuels. The

waste PEG cutting oil from wafer cutting

contains 40~50% tiny

silica powder, which can not be filtered

even within 0.5μm filter bag

(as

figure

below). The

silica powder bridging agent can be added

to the PEGcutting oil to condensate the

tiny silica powder and filter the PEG

cutting oil

that is clarified effectively; can be

used for metal processing or boiler

fuels.

|

|

|

|

PowerWash™TRM(Thermal

Resist Masking tape) Glue Eraser |

|

|

PowerWash™ TRM Glue Eraser is used to

remove the residual silica glue left by

the masking tape that contracts and is

stripped off in backing after IC

packaging on the metal plate. Let the

plate that contains residual silica glue

stand still in the fixture for cleaning

in the ultrasonic cleaning machine, take

it out and put in the water jet that

contains resin sand for spray washing to

remove the residual glue effectively.

More.. |

|

|

|

PowerWash™Epoxy

Resin Cleaner(Chemical Epoxy glue

Cleaner) |

|

|

The traditional electrolytic glue

removal process is not suitable for the

barium plated plates in the new IC

packaging process. The packaging

material epoxy has very good chemical

tolerance. PowerWash™ Epoxy Cleaner can

penetrate into the interface existing

between two different materials: barium

and epoxy to remove the epoxy glue that

overflows.

More.. |

|

|

|

|

UniMagic™Electrolysis

Epoxy

Resin

Cleaner

Added to

the

electrolytic

bath to

run the

electrolytic

process

at 5V

100A

current;

effectively

removes

the

copper

sheet

epoxy

glue

overflowing

and the

tiny

quantity

of oil

film,

dust and

ash. |

|

|

|

UniMagic™Electrolysis

Degreasing

Agent

Added to the

electrolytic

bath to run

the

electrolytic

process at

5V 100A

current;

effectively

removes the

copper sheet

oil and the

tiny

quantity of

dust and

ash.

|

|

|

PowerWash™Lens

acrylic glue Cleaner |

|

When put in the

fixture for

cleaning in the

ultrasonic

cleaning

machine, the

cleaner can

effectively

remove the

acrylic glue,

shellac (insect

glue) and

chocolate glue

that are most

difficult to

remove bonding

on the mold (s)

or glass

mirrors. After

taking it out,

put it into a

pure water bath

for washing.

Free from toxic

halogen elements

such as

fluorine,

chlorine and

bromine. Free

from benzene and

aromatic organic

solvents; will

not given of bad

odor when

cleaning at high

temperature.

Good water

permeability,

low foam, can be

washed clean

rapidly with

plenty of fresh

water without

any residue. Has

good biological

degradability

and conforms to

the

environmental

protection

requirements.

More.. |

|

UniMagic™Super

Glue Cleaner

(Synonym: Photo

Mask Glue Cleaner,

Natural Acrylic Glue

Eraser) |

|

|

The Pellicle can

maintain the mask

clean and blur the

shadow caused by the

dust upon

photographing.

However, the glue

remaining on the

mask after the use

of Pellicle creates

the problem of mask

cleaning. The

natural glue remover

extracted from

orange is a new

natural,

toxicity-free,

environment-friendly

and low volatility

solvent that can

easily soften and

break down the

filming structure of

various backing

glue, acrylic glue

and silicon glue,

prevents re-affixing

of backing and

therefore increase

the work efficiency.

More.. |

|

|

PowerWash™Copper

Blade Plastic Membrane Eraser |

|

|

The copper sheets used on the carbon

powder boxes of laser printers were

covered with a thin layer of film to

protect them against damages. In the

past, the workers needed to strip off the

film manually and remove the glue by

wiping, which, in addition to being time

and labor consuming, might decrease the

yield due to possible scratches.

PowerWash™ Copper Blade Plastic Membrane

Eraser improves the traditional film

removing process. The new process only

requires soaking the copper sheets and

thin film in the film remover for 5

minutes, taking off the thin film after

it is expanded and moistened and washing

it with fresh water. Removal of several

hundreds thousands and even millions of

films can be done simultaneously within

10 minutes. No wiping is required and the

defect rate is “zero”.

More.. |

|